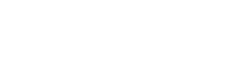

CLEARCERAM®-Z

Glass-ceramic with an Ultra-Low Thermal Expansion Coefficient and developed by High Homogeneity melting and Precise Crystallization.Key Properties of CLEARCERAM®-Z

Ultra-Low Expansion Glass

CLEARCERAM®-Z shows almost Zero Thermal Expansion over a wide temperature range and offers superior thermal shock resistance. CCZ Regular offers lower thermal expansion across a wide temperature range, while the CCZ-HS offers lower thermal expansion near room

Superior Mechanical Properties

CLEARCERAM®-Z is comprised of approximately 70% ceramic material, which makes the mechanical characteristics superior to regular amorphous glass when comparing properties such as Young’s Modulus, Rigidity, Bending Strength, and Knoop Hardness.”

Superior Machinability

The crystal grain structure of CLEARCERAM®-Z prevents the propagation of microscopic cracks that can be caused in between machining processes. This property gives the material superior machinability and allows it to be processed into various shapes with high accuracy and elevated yield rates.

Excellent Chemical Properties

CLEARCERAM®-Z has very high chemical durability and stability in various cleaning and thin-film coating processes. The material composition does not contain Na, K, B, F, or Pb, which is a main reason for the excellent chemical resistance.

Applications for CLEARCERAM®-Z

CLEARCERAM®-Z is used for semiconductor stepper components, liquid crystal stepper components, optical flats, spacers, windows, interferometer components, laser refraction mirrors and suspensions, astronomical telescope mirrors, block gauges, long precision scales, optical pedestal platforms, and pedestals for precision equipment. This material is an ideal alternate to quartz glass, ceramics, or low thermal expansion alloys.

Please contact us for additional details about CLEARCERAM®-Z- Ultra Low Expansion Glass.

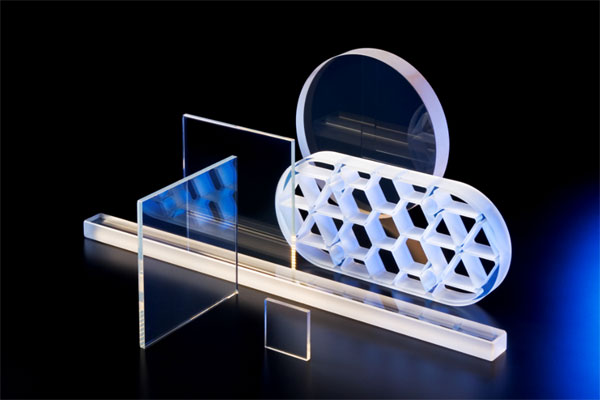

Author: Jay Bennett for Popular Mechanics

Feb 14, 2018

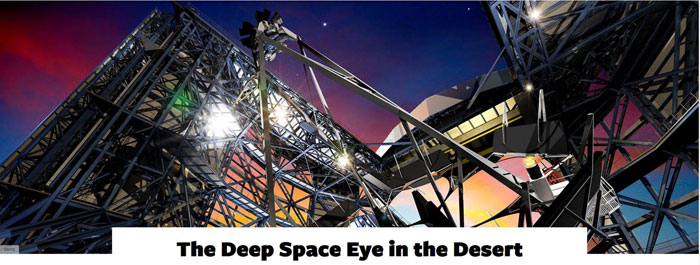

‘Laser Focus World – December 2008’

The LSST mirror [made from Ohara E6 glass] has been cast and is ready for grinding and polishing. The outer 5.0 to 8.4 meter diameter portion will serve as the primary mirror; the inner 5.0 meter diameter portion will be ground to a steeper curvature and will become the telescope’s tertiary mirror. (Courtesy of Laser Focus World and the University of Arizona)